Top 8 Industrial Applications of Sheet Metal Fabrication

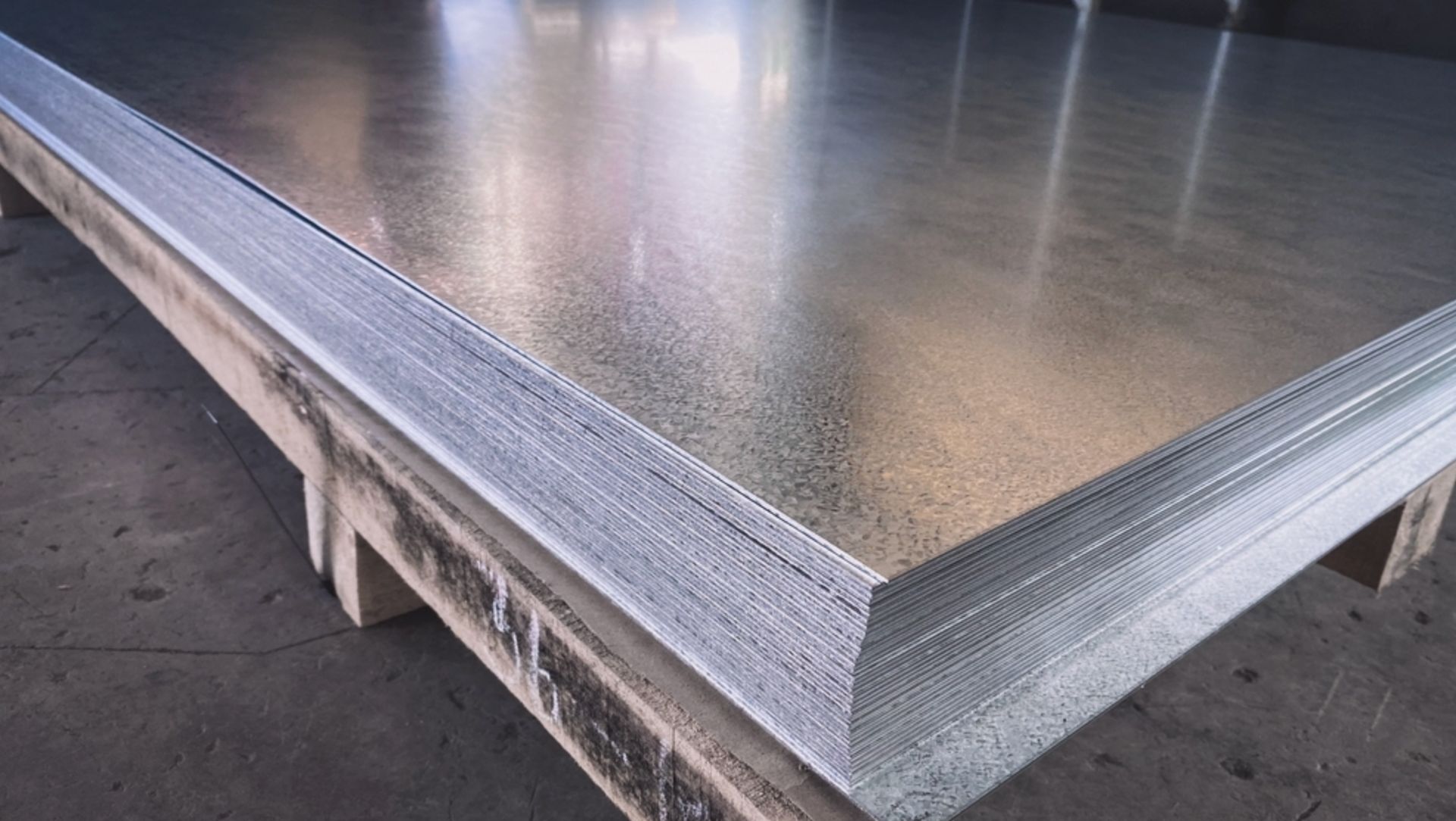

Have you ever stopped to think about how many structures, machines, and systems around you are made possible by sheet metal fabrication? From the frame of a building to the ductwork in your ceiling, fabricated metal plays a silent yet vital role in modern life. Sheet metal fabrication involves cutting, bending, and shaping metal sheets into components used in various industries. Its popularity comes down to its durability, adaptability, and ability to be customised for specific needs. In this blog, we’ll explore the top 8 industrial applications of sheet metal fabrication and how they contribute to different sectors.

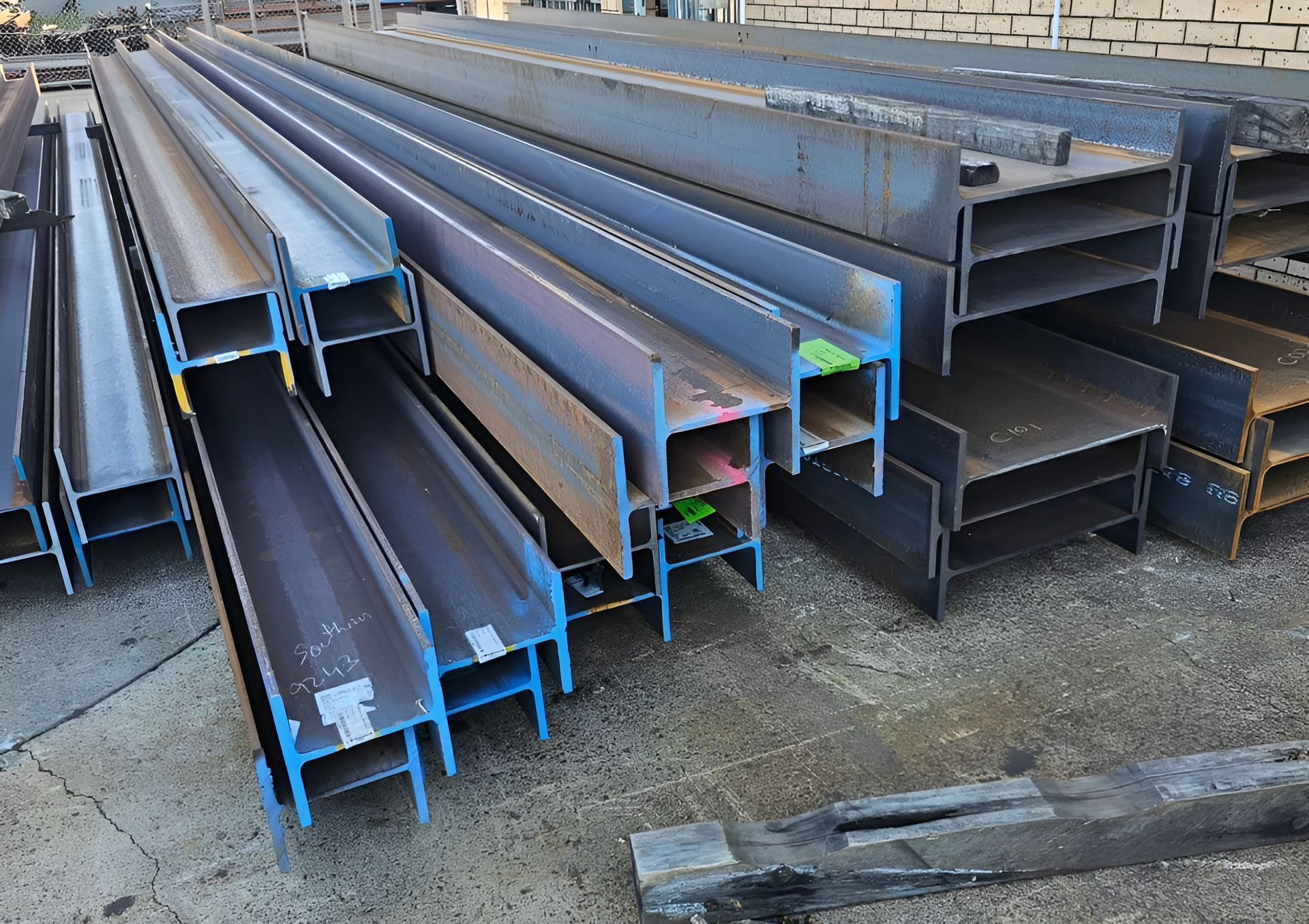

1. Construction & Structural Framework

In construction, structural steel fabrication on the Sunshine Coast is a core element of creating buildings that are both strong and long-lasting. Sheet metal components are used in everything from high-rise support frames to roofing panels and exterior cladding. The versatility of steel allows it to be tailored to meet the unique demands of different projects, whether that’s withstanding heavy loads, resisting corrosion, or fitting precise architectural designs. With its adaptability, sheet metal is an integral part of both commercial and residential builds, as well as infrastructure projects such as bridges and walkways.

2. Automotive Manufacturing

The automotive industry relies heavily on sheet metal fabrication for producing car bodies, chassis structures, and safety frames. Steel and aluminium sheets are shaped to create panels that provide both durability and crash protection. One of the advantages of using fabricated sheet metal is its high strength-to-weight ratio, which contributes to improved fuel efficiency without compromising structural integrity. Beyond mass-produced vehicles, custom fabrication supports specialty vehicles, including utes, trailers, and performance cars. Precision in fabrication also plays a role in ensuring that components fit seamlessly, supporting both functionality and aesthetics.

3. HVAC Systems

Heating, ventilation, and air conditioning systems depend on precisely fabricated sheet metal to function effectively. Ductwork, vents, and air handling unit casings are all made from sheet metal due to its strength, resistance to wear, and ability to be formed into complex shapes. Accuracy in fabrication ensures that airflow is distributed evenly and efficiently throughout buildings, helping maintain comfort and air quality. On the Sunshine Coast, where climate control is important year-round, having well-made sheet metal components is essential for both residential and commercial HVAC systems.

4. Marine Industry

In coastal regions, the marine industry benefits from the corrosion-resistant qualities of fabricated sheet metal, particularly stainless steel and aluminium. Boats, ships, and marine equipment often feature metal components such as hulls, decks, railings, and storage compartments. Fabrication techniques can be adapted to meet the unique challenges of the marine environment, including exposure to saltwater, humidity, and varying temperatures. In addition to structural parts, sheet metal fabrication supports custom fittings and fixtures that enhance functionality and safety on board vessels.

5. Mining & Heavy Equipment

Mining operations demand equipment that can withstand extreme conditions, and sheet metal fabrication plays a vital role in meeting these requirements. Components such as machinery guards, reinforced enclosures, and conveyor systems are often built from fabricated steel to endure the constant wear and tear of mining activities. The ability to customise thickness, coatings, and designs means that fabricated parts can be optimised for maximum lifespan in abrasive or corrosive environments. Heavy equipment manufacturers also rely on sheet metal for panels, brackets, and operator cabins that combine durability with safety considerations.

6. Agriculture & Farming Equipment

Agriculture is another industry where sheet metal fabrication proves its worth. Farm machinery and equipment need to be sturdy, weather-resistant, and able to handle heavy workloads. Fabricated sheet metal is commonly used for silos, grain bins, irrigation systems, and tractor parts. These components are designed to resist rust, impact damage, and environmental wear. For farmers, the dependability of well-fabricated metal equipment can make a noticeable difference in productivity and operational efficiency, especially during peak seasons when downtime must be avoided.

7. Energy & Utilities

The energy sector, including renewable energy projects, depends on sheet metal fabrication for a variety of applications. Solar panel frames, wind turbine housings, and electrical enclosures are all manufactured using fabricated metal. In power generation facilities, sheet metal is used for ventilation systems, protective covers, and structural supports. The ability to create custom components to meet specific technical and environmental requirements makes sheet metal fabrication an ideal choice for the energy industry, where durability and precision are equally important.

8. Food Processing & Hospitality

In industries where hygiene is a priority, such as food processing and hospitality, sheet metal fabrication is essential. Stainless steel is the material of choice for benches, sinks, storage units, and food preparation equipment due to its non-porous surface and resistance to corrosion. The smooth finish of fabricated stainless steel makes it easy to clean and maintain, supporting food safety standards. In restaurants, commercial kitchens, and catering facilities, custom sheet metal solutions can also improve workflow efficiency by providing equipment that fits specific spaces and operational needs.

Why Sheet Metal Fabrication is So Versatile

One of the reasons sheet metal fabrication is so widely used is its adaptability to different shapes, sizes, and finishes. It can be cut, bent, punched, and welded to meet the exact requirements of a project. This flexibility allows industries to benefit from components that are designed for their unique applications, whether that means added strength, improved corrosion resistance, or better aesthetics. In addition, advances in fabrication technology, such as laser cutting and CNC machining, allow for higher precision and faster turnaround times.

Maintenance & Longevity

While the initial fabrication process is important, so is the long-term care of sheet metal products. Regular inspection, cleaning, and maintenance can extend the lifespan of fabricated components, reducing the need for frequent replacements. In sectors such as marine, mining, and construction, preventive maintenance is especially important to protect against environmental damage and heavy wear. Applying protective coatings, using corrosion-resistant alloys, and following industry-recommended care practices can help maintain both the performance and appearance of fabricated metal products.

Get Custom Sheet Metal Solutions for Your Industry Today

From construction sites to commercial kitchens, sheet metal fabrication plays an important role in creating durable, functional, and adaptable components across a range of industries. Each sector benefits from its versatility, whether it’s through structural steel frameworks, custom-fitted equipment, or precision-engineered parts.

At On the Spot Steel Fabrication, steel fabrication on the Sunshine Coast is tailored to meet the needs of various industrial applications, delivering high-quality results that align with industry demands.

Contact us today to discuss your next fabrication project and see how our team can bring your concept to life.