Structural Steel Fabrication: What Makes A Strong, Compliant Build

Structural steel plays a critical role in modern construction. From residential builds to large-scale commercial and industrial projects, steel frameworks provide the strength, stability and flexibility that many structures rely on.

However, not all steel structures perform the same. The difference between a reliable, long-lasting build and one that develops issues often comes down to fabrication quality and compliance. Structural steel fabrication is not simply about cutting and welding steel, it is about precision, standards and understanding how loads move through a structure.

This article explains what defines quality structural steel fabrication on the Sunshine Coast, why compliance is essential and how fabrication standards directly affect safety and performance.

What Is Structural Steel Fabrication?

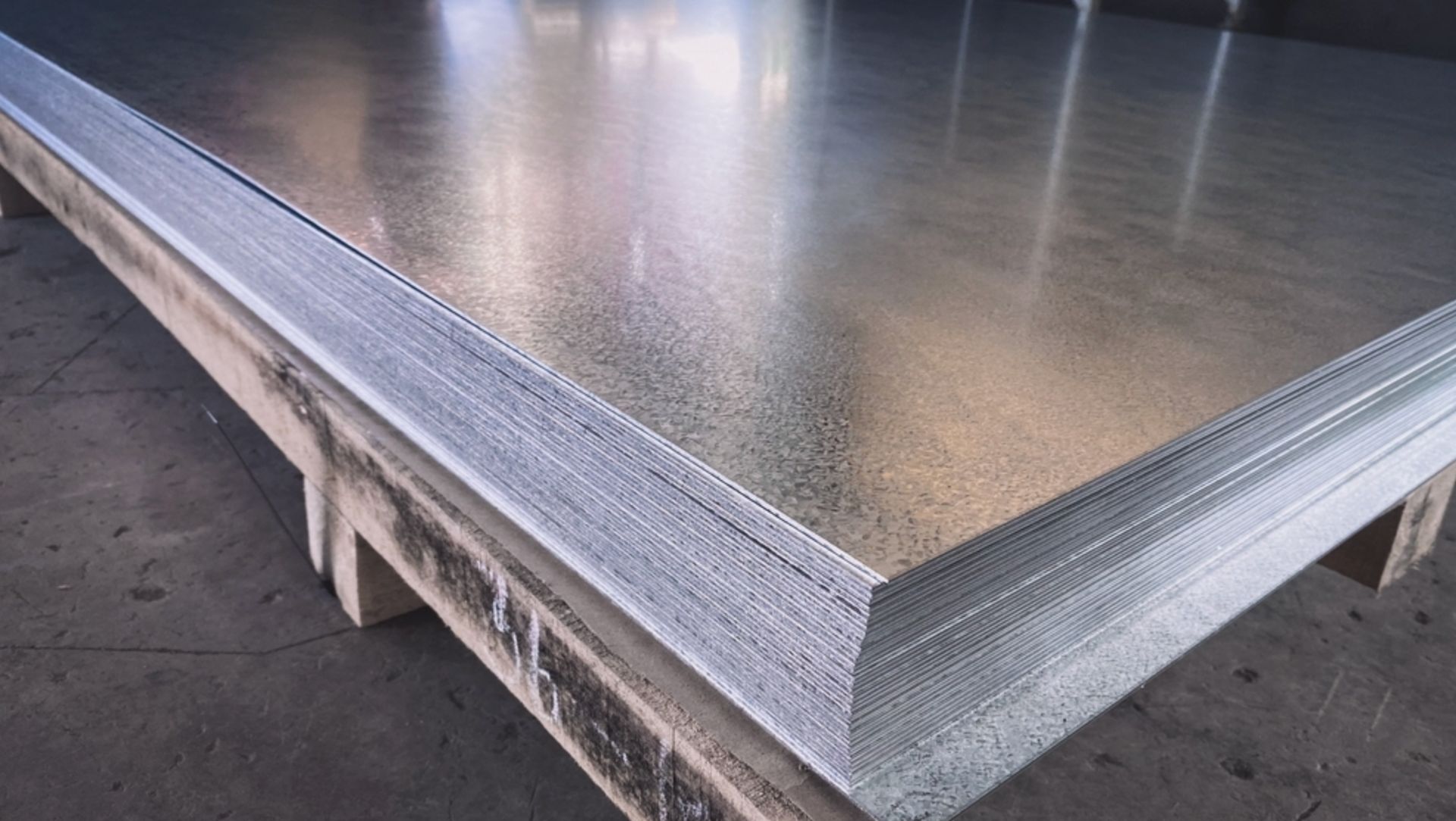

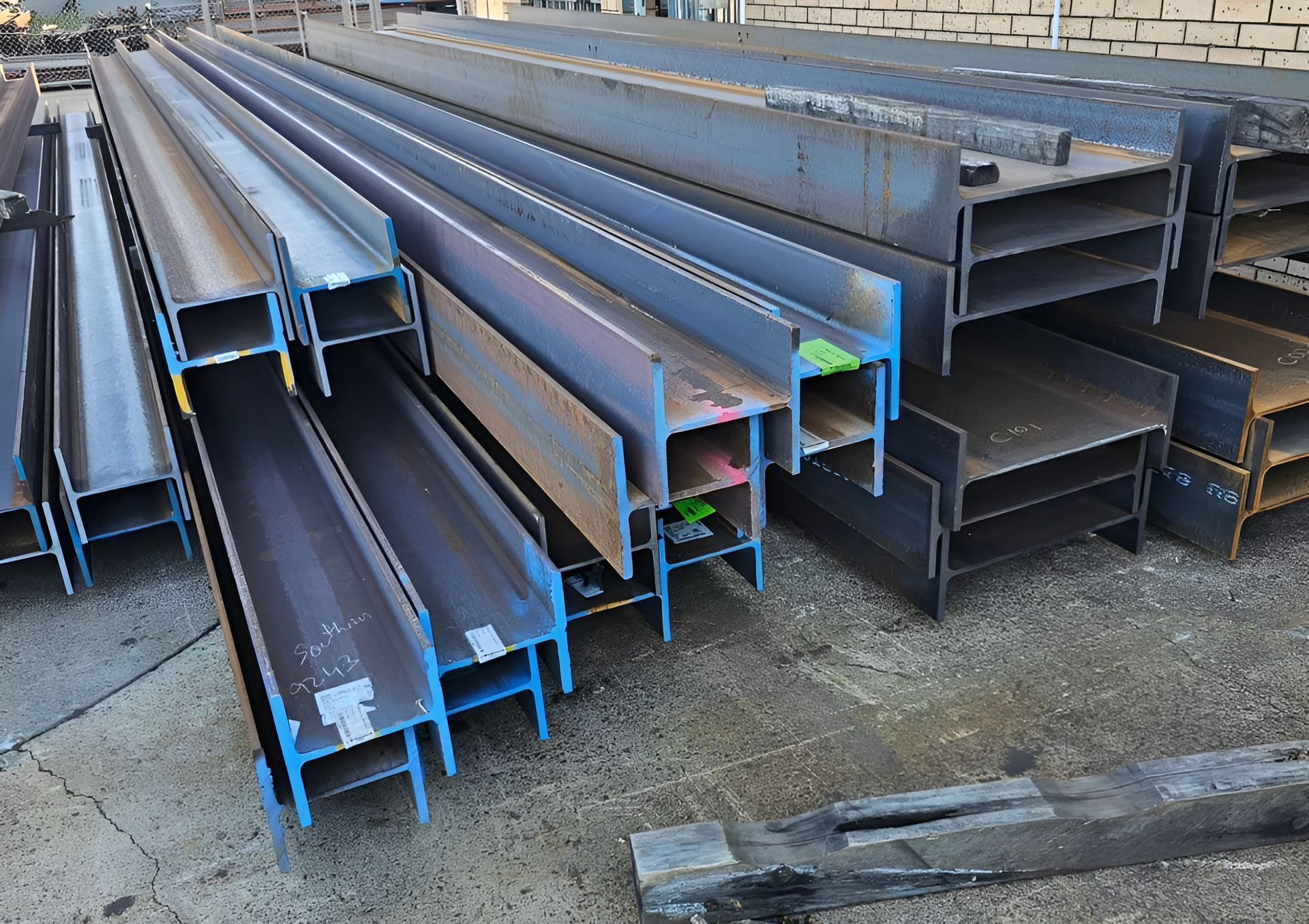

Structural steel fabrication refers to the process of transforming raw steel materials into load-bearing components used in construction. These components are designed to support weight, resist movement and integrate with other structural elements.

Fabrication typically involves cutting, welding, drilling and assembling steel to exact specifications. Each element must align with engineering designs to ensure the structure performs as intended once installed.

Unlike decorative steelwork, structural steel carries responsibility for the safety and integrity of the entire build.

Why Structural Steel Is Central to Modern Construction

Steel is widely used because of its strength-to-weight ratio, durability and adaptability. It allows designers and engineers to achieve spans and forms that would be difficult with other materials.

In practical terms, structural steel on the Sunshine Coast benefit from steel’s ability to handle coastal conditions when specified and fabricated correctly. Steel structures can be designed to accommodate wind loads, live loads and long-term stresses common in the region.

This makes steel an essential component in many residential, commercial and industrial builds.

What Defines Structural Steel Fabrication Quality

Quality fabrication begins long before steel is cut or welded. It starts with accurate interpretation of engineering drawings and a clear understanding of how components interact.

Key factors that define quality fabrication include:

- Precision cutting and accurate dimensions

- Correct welding techniques and penetration

- Proper alignment and fit-up of components

- Adherence to engineering tolerances

Even small inaccuracies can compromise how loads are transferred through the structure.

Load-Bearing Integrity and Structural Performance

Structural steel components are designed to carry specific loads. These loads may include the weight of the building itself, occupants, equipment and environmental forces such as wind.

When fabrication is accurate, loads are distributed as designed. When fabrication quality is poor, stress can concentrate in unintended areas, increasing the risk of deformation or failure.

Load-bearing integrity depends on each fabricated component performing its role exactly as specified.

Why Compliance Is Critical in Steel Structures

Compliance in structural steel fabrication is not optional. Australian Standards and building regulations exist to ensure safety, consistency and reliability across construction projects.

Compliance affects:

- Structural performance under load

- Long-term durability

- Approval and certification processes

- Insurance and liability outcomes

Non-compliant fabrication can lead to costly delays, rework or rejection during inspections.

Australian Standards and Structural Steel Fabrication

Structural steel fabrication in Australia must align with relevant standards governing materials, welding and fabrication practices.

Compliance typically covers:

- Material grades and specifications

- Welding procedures and qualifications

- Fabrication tolerances

- Quality control processes

Experienced fabricators understand these requirements and integrate them into every stage of production.

The Role of Welding in Structural Safety

Welding is one of the most critical aspects of structural steel fabrication. Welds must be strong enough to transfer loads without cracking or fatigue.

Quality welding requires:

- Qualified welders

- Appropriate welding methods for the steel type

- Correct preparation and joint design

Poor welding can undermine even well-designed structures, making fabrication expertise essential.

How Fabrication Quality Impacts Safety on Site

Fabrication quality directly affects site safety during installation. Components that fit correctly are easier and safer to install.

High-quality fabrication helps:

- Reduce on-site modifications

- Minimise handling risks

- Ensure proper alignment during erection

This contributes to safer working conditions for construction teams and more efficient project timelines.

Coastal Conditions and Steel Fabrication on the Sunshine Coast

Sunshine Coast builds face unique environmental challenges, including humidity and salt exposure. These factors must be considered during material selection and fabrication.

Local fabricators understand how coastal conditions affect steel over time. Appropriate coatings, finishes and fabrication methods help reduce corrosion risk and extend service life.

This local insight is particularly important for long-term structural performance.

Why Experienced Fabricators Matter

Structural steel fabrication requires technical skill, attention to detail and a strong understanding of engineering intent. Experience allows fabricators to identify potential issues before they become problems.

Experienced fabricators provide:

- Accurate interpretation of drawings

- Consistent fabrication quality

- Reliable communication with builders and engineers

This experience supports smoother project delivery and fewer issues on site.

Collaboration Between Fabricators, Engineers and Builders

Successful steel structures rely on collaboration. Fabricators work closely with engineers and builders to ensure components meet design requirements and site constraints.

Clear communication helps:

- Resolve design queries early

- Avoid fabrication errors

- Ensure components integrate seamlessly

This collaborative approach supports strong, compliant outcomes.

Quality Control Throughout the Fabrication Process

Quality control is not a single step, it is an ongoing process throughout fabrication.

Effective quality control includes:

- Checking measurements at each stage

- Inspecting welds and joints

- Verifying materials meet specifications

Consistent checks help ensure finished components meet both design and compliance requirements.

Long-Term Performance Depends on Fabrication Standards

The true test of structural steel fabrication is how it performs over time. Accurate fabrication contributes to structures that maintain alignment, resist fatigue and meet their design life.

Investing in quality fabrication reduces the risk of future structural issues and costly remediation.

Structural Steel Fabrication Sunshine Coast Projects Can Rely On

Structural steel fabrication is a critical element in creating strong, compliant and safe buildings. From load-bearing integrity to regulatory compliance, fabrication quality affects every stage of a project.

On The Spot Fabrication provides structural steel fabrication on the Sunshine Coast. Our team delivers high-quality structural steel solutions with a focus on precision, compliance and long-term performance.

If you’re planning a project that depends on reliable structural steel,

contact On The Spot Fabrication to discuss your requirements with a local fabricator who understands what strong, compliant builds demand.