Understanding the Corrosion Resistance of Aluminium & Steel

When planning construction, marine, or industrial projects, one of the most important considerations is how well your chosen material will perform over time. Both aluminium and steel are widely used in fabrication for their strength, versatility and cost-effectiveness. However, their ability to resist corrosion differs significantly.

Understanding the strengths and vulnerabilities of each material can help project managers and property owners choose wisely. Whether considering aluminium fabrication on the Sunshine Coast or opting for steel on the Sunshine Coast, knowing how these metals behave in different environments is essential for durability and value.

Why Corrosion Resistance Matters in Fabrication

Corrosion is the natural deterioration of metal caused by exposure to air, moisture, and chemicals. For industries and property owners, corrosion resistance directly affects a project's lifespan, safety and cost. Some of the reasons corrosion resistance should be prioritised include:

- Corrosion weakens structural integrity, increasing the risk of failures.

- Repairs and replacements from corrosion damage can be expensive and disruptive.

- In marine and coastal areas, salt and humidity accelerate corrosion significantly.

- Choosing the right material reduces long-term maintenance needs and costs.

Selecting materials suited to the environment ensures better performance and reduced lifecycle costs.

The Natural Corrosion Resistance of Aluminium

One of aluminium’s most significant advantages is its natural corrosion resistance. When exposed to air, aluminium forms a thin oxide layer on its surface. This layer is a barrier, protecting the underlying metal from further deterioration.

This property makes aluminium particularly well-suited for coastal and marine applications. Unlike untreated steel, it won’t rust or flake. Instead, the protective oxide coating regenerates if scratched, maintaining long-term resistance.

Because of this, aluminium fabrication on the Sunshine Coast is a popular choice for projects exposed to high humidity, sea spray and constant weather changes. It’s lightweight, durable and requires minimal upkeep, making it ideal for balustrades, outdoor furniture and marine structures.

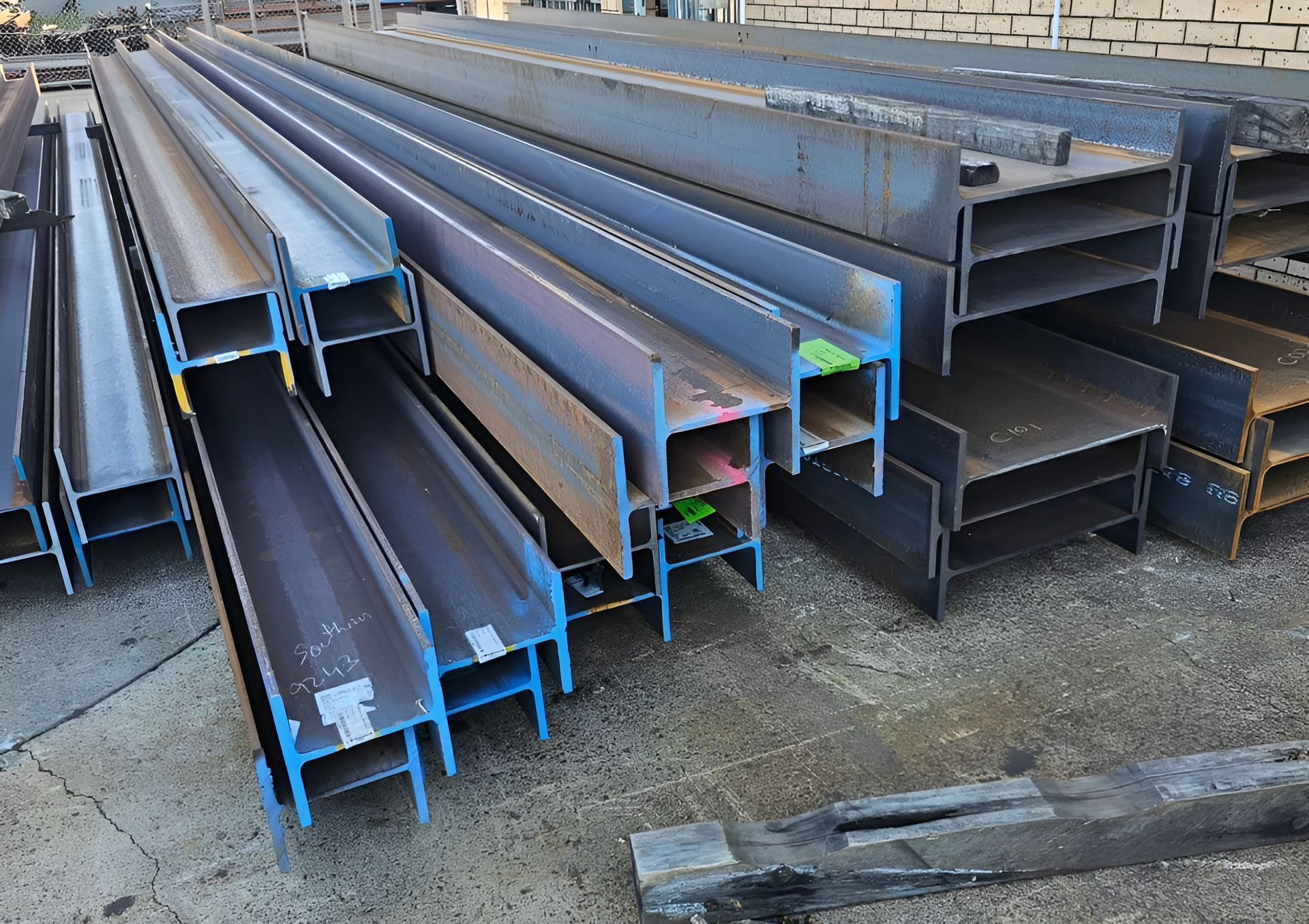

The Strengths & Vulnerabilities of Steel

Steel is renowned for its strength and versatility. It’s the backbone of construction, used for everything from beams and frames to heavy machinery. However, steel has one major vulnerability—it corrodes easily when exposed to moisture and oxygen without protection.

Rust affects appearance and compromises the material’s structural integrity. Untreated steel can deteriorate quickly in harsh coastal environments, making it unsuitable without added protection.

That said, steel remains a vital material for projects requiring exceptional strength. Steel can balance its natural durability with corrosion resistance when appropriately treated, giving project managers the best of both worlds.

Protective Treatments for Steel on the Sunshine Coast

Fortunately, steel can be treated in several ways to enhance its corrosion resistance. The correct method depends on the intended use, exposure conditions and budget. Some of the most common treatments include:

- Galvanising: A protective zinc coating is applied to steel, preventing moisture from reaching the metal beneath.

- Powder coating or painting: Layers of protective coating create a barrier that resists moisture, chemicals and UV damage.

- Stainless steel alloys: Incorporating chromium and other elements enhances natural corrosion resistance, which is ideal for marine or high-exposure applications.

- Cathodic protection: This method redirects corrosion to a “sacrificial” metal instead of the main steel structure in industrial settings.

By applying these treatments, Steel fabrication on the Sunshine Coast can deliver both the strength of steel and the resilience needed for long-term outdoor use.

Comparing Aluminium & Steel in Harsh Environments

When choosing between aluminium and steel, it’s essential to consider how each performs in specific conditions.

Marine Environments

Aluminium is naturally more resistant to saltwater, making it a preferred choice for boats, pontoons and coastal structures. Steel can still be used, but stainless alloys or protective coatings are required to avoid rust.

Construction Projects

Steel remains unmatched in strength and is ideal for load-bearing structures and reinforcements. Aluminium is lighter and easier to handle, making it valuable for non-structural elements like railings and cladding.

Industrial Applications

Both metals have their place in industrial settings. Steel’s strength suits heavy machinery, while aluminium is chosen for applications where weight reduction and corrosion resistance are priorities.

Project managers achieve both efficiency and durability by aligning material selection with environmental demands.

Maintenance Requirements for Long-Term Durability

The level of maintenance required is another factor to consider when choosing between aluminium and steel. Aluminium is naturally low-maintenance thanks to its self-protecting oxide layer. It may require occasional cleaning, but generally resists deterioration even in challenging conditions. Steel, on the other hand, requires ongoing inspection and upkeep. Coatings must be reapplied periodically, and untreated steel must be monitored closely for signs of rust. While stainless steel reduces these concerns, it comes at a higher upfront cost.

Factoring in maintenance helps determine the actual long-term value of each material.

Choosing the Right Material for Your Project

Deciding between aluminium and steel depends on your project's unique needs. Both offer distinct benefits, but the right choice balances strength, resistance and cost-effectiveness. Some practical points to guide your decision include:

- Aluminium is generally the safer, low-maintenance choice for coastal or marine applications.

- Steel — when treated properly — for projects demanding maximum structural strength remains the best option.

- For long-term durability with minimal upkeep, aluminium often offers better lifecycle value.

- Steel fabrication on the Sunshine Coast provides the reliability required for custom or high-load industrial projects.

By weighing these factors, property owners and project managers can select the material that best suits the environment and the function.

Partnering With Local Experts in Fabrication

Ultimately, choosing between aluminium and steel is not a one-size-fits-all decision. Each project has unique requirements, and the right material choice comes from balancing performance, environment and budget. This is where professional advice makes all the difference.

Engaging local experts in aluminium fabrication or steel fabrication on the Sunshine Coast ensures your project benefits from materials tailored to local conditions. Skilled fabricators not only supply high-quality products but also provide insights into which material is best suited to your application.

Get Expert Advice on Aluminium & and Steel Fabrication

At

On The Spot Fabrication, we provide professional aluminium fabrication and trusted steel fabrication for projects of all sizes. Whether you need lightweight aluminium for coastal use or robust steel for structural strength, our team delivers tailored solutions that meet your needs.

Contact us today for expert guidance on the best material for your next project.