The Most Common Types Of Metal Used In Fabrication (And Why They Matter)

When you’re planning a project that involves metalwork, material choice shapes everything: performance, lifespan, weight, cost, and even how the finished structure looks. Many property owners and project managers reach out to us with a clear idea of what they want to build, but not always a clear understanding of which metal will serve them best in the long run. With aluminium fabrication on the Sunshine Coast projects becoming more popular across architectural, commercial and marine builds, it’s worth taking a closer look at how each metal behaves and why the differences matter.

Every metal brings its own strengths. Aluminium holds its ground in coastal environments. Mild steel stays dependable across heavy-duty builds. Stainless steel keeps its clean finish even when exposed to heat and harsh conditions. Structural steel gives large-scale projects the backbone they need. Understanding these differences helps you pick a material that supports your budget, timeline and intended use without surprises down the track.

Below, we dive into the most common metals used in fabrication today. If you’re comparing quotes or weighing up design priorities, this guide gives you a clear picture of how each option performs in real-world settings.

Aluminium: Lightweight Performance with Natural Corrosion Resistance

Aluminium has become a favourite across the Sunshine Coast thanks to its strength-to-weight ratio and its natural resistance to corrosion. You’ll see it used in architectural screens, boat components, balustrades, gates, custom brackets and outdoor fixtures. Its ability to hold strong without adding significant weight makes it ideal for applications where structure needs to perform without feeling bulky.

One of aluminium’s greatest strengths is the protective oxide layer that forms as soon as it contacts the air. That layer prevents rust from forming, which makes it perfect for humid and coastal locations. When you’re working near the ocean or in exposed outdoor spaces, Sunshine Coast aluminium fabrication projects often outlast alternatives because they don’t need constant upkeep.

Aluminium also responds well to

cutting, machining and welding. It bends cleanly without losing its integrity, which gives designers more freedom to explore curved lines, slim profiles and modern architectural styles. Property owners appreciate the low maintenance. Project managers appreciate the predictable performance. Fabricators appreciate how cooperative it is when shaping detailed components.

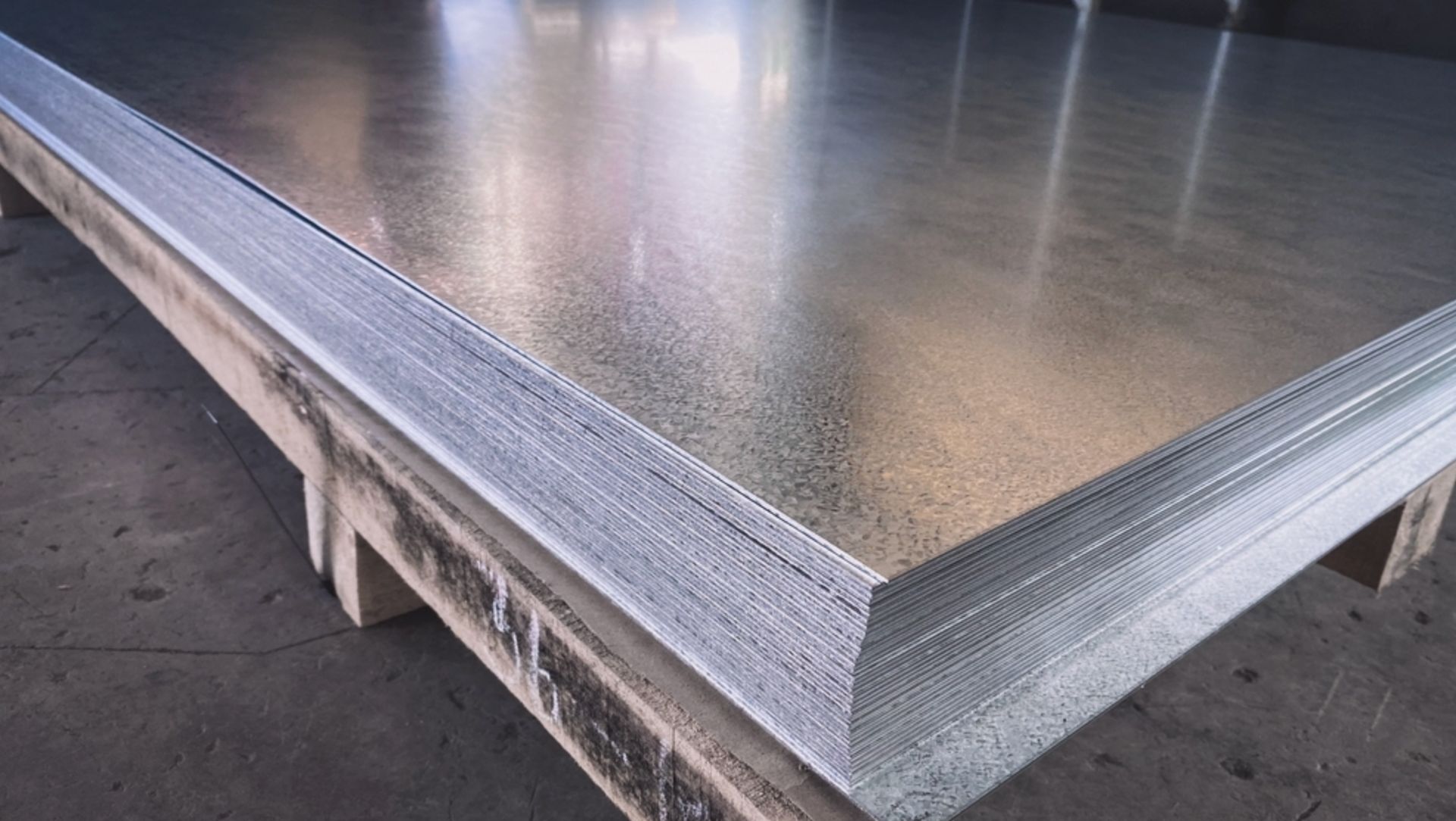

Mild Steel – Tough, Adaptable & Budget-Friendly

Mild steel sits at the heart of countless everyday fabrication projects. Its combination of strength, affordability and versatility makes it one of the most widely used metals in workshops across Australia. If you’re building frames, brackets, handrails, trailer bodies or general structural pieces, mild steel gives you dependable strength without blowing out your material budget.

Its low carbon content makes it easier to weld than high-carbon steels. That means cleaner joins, fewer distortions and quicker turnarounds. For large commercial projects, this helps keep timelines tight. For homeowners tackling renovations or extensions, it keeps fabrication accessible and cost-conscious.

One thing to keep in mind is mild steel’s susceptibility to rust. Untreated mild steel corrodes quickly, especially near the coast.

Protective coatings, primer and paint play an important role in maintaining its lifespan. With the right finish, mild steel becomes far more resilient. This balance of affordability and performance is why building with steel on the Sunshine Coast often begins with mild steel, when the environment allows for proper coating and maintenance.

Stainless Steel – Strength with Long-Term Visual Appeal

When your project demands both durability and a polished finish, stainless steel ticks those boxes. Stainless steel’s chromium content gives it excellent resistance to rust and staining, making it popular for kitchens, commercial environments, architectural features and any area where cleanliness matters.

Stainless steel comes in several grades, each suited to different conditions. Grade 304 works well indoors where moisture exposure is minimal. Grade 316 stands up to harsh outdoor environments and regular water contact. Many coastal builds lean toward 316 for handrails, lighting brackets, bollards and marine components because it keeps its appearance even in salty air.

Stainless steel’s strength also shines in fabrication. It holds its shape well and tolerates high temperatures. Those qualities matter in industrial settings, commercial kitchens and fire-rated structures. While stainless steel costs more upfront, its long-term performance often justifies that investment. Low maintenance and a clean finish make it a popular choice when appearance is just as important as function.

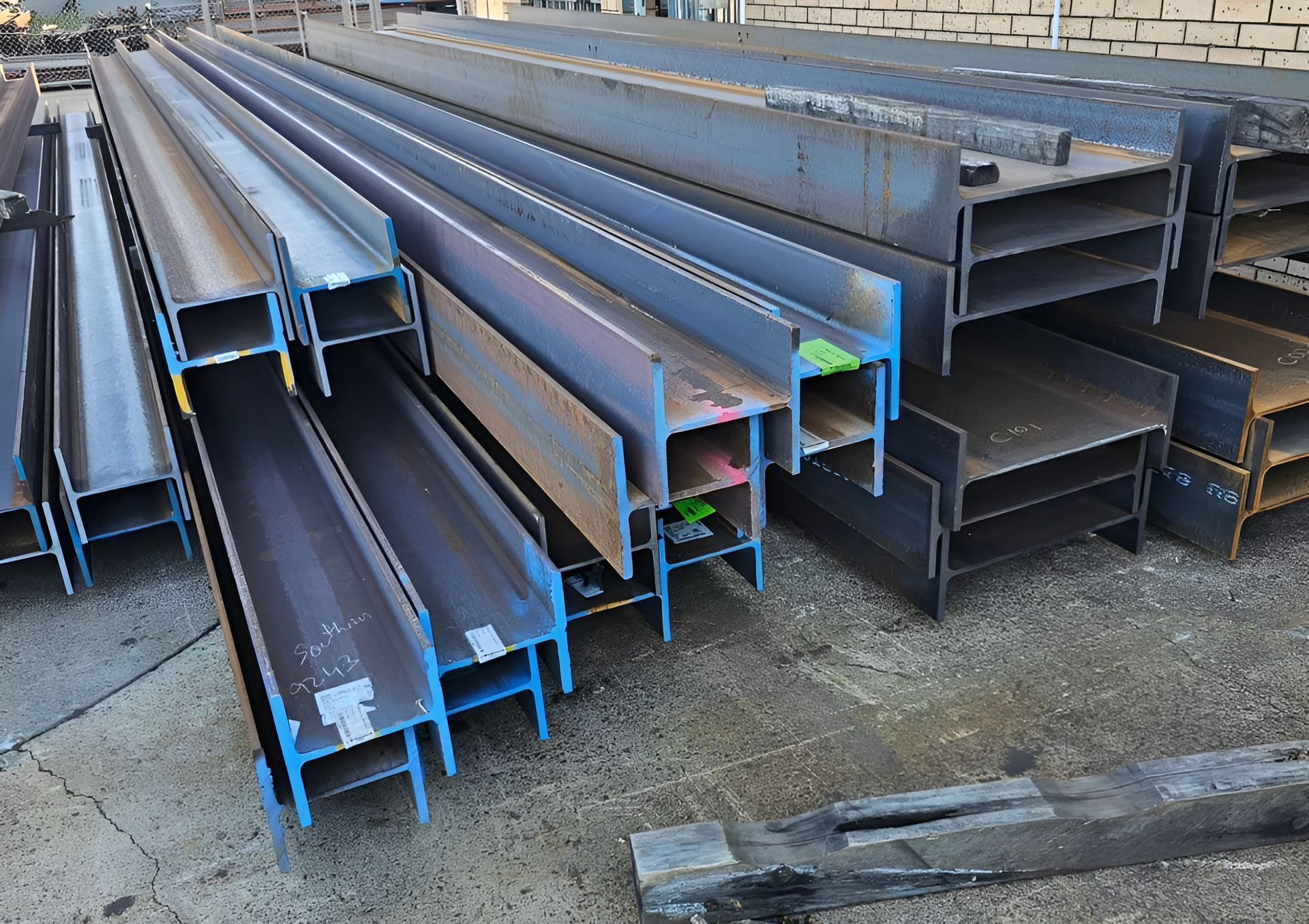

Structural Steel – the Backbone of Major Builds

Structural steel supports the bones of buildings, bridges, commercial complexes and major infrastructure. Its high tensile strength allows it to carry heavy loads without bending or warping. You’ll find structural steel in beams, columns, trusses, portals and frames that form the foundation of everything from industrial sheds to multi-storey buildings.

When project managers talk about steel fabrication in the Sunshine Coast construction, they often mean structural steel. This material handles stress exceptionally well. It holds its shape under load and maintains stability across large spans. Engineers love the predictability. Builders love the efficiency. Project owners love the longevity and value.

Another advantage is precision. Structural steel fabrication works hand-in-hand with detailed engineering drawings. Precise cutting,

drilling and welding allow fabricated components to fit perfectly during installation. This reduces on-site delays and keeps construction flowing smoothly. Combined with coatings to protect against corrosion, structural steel delivers a long service life with minimal maintenance.

Why Metal Selection Affects More Than Price

When you’re choosing between aluminium, mild steel, stainless steel or structural steel, price is only part of the equation. Material selection influences:

Lifespan

Corrosion resistance, exposure and required maintenance all factor into long-term value.

Weight

Lighter metals like aluminium reduce load-bearing needs and installation handling.

Strength

Structural steel and stainless-steel carry loads and resist impact better than other options.

Appearance

Stainless steel gives a clean, modern finish, while mild steel adapts to painted and coated looks.

Environmental Exposure

Coastal, industrial and high-traffic areas each demand different tolerances.

Fabrication Complexity

Some metals bend, weld and cut with ease while others require specialised skills or equipment.

When property owners and project managers understand these differences, decision-making becomes far easier. With a clear picture of how each metal behaves, you can plan a project that aligns with your priorities without unexpected maintenance or structural issues later.

Matching the Right Metal to the Right Job

Below is a quick guide for choosing the best metal for your project.

Choose aluminium if you want…

- Lightweight components

- Strong corrosion resistance

- Modern architectural styling

- Durable outdoor or marine features

- Easy maintenance

Choose mild steel if you want…

- Cost-effective fabrication

- Strong performance

- Flexibility across shapes and applications

- A material that works well with coatings and paint

Choose stainless steel if you want…

- A polished or clean finish

- Excellent resistance to heat, moisture and staining

- Long-term performance in harsh environments

- Hygiene-friendly surfaces

Choose structural steel if you want…

- Load-bearing strength

- A reliable frame for large projects

- Long spans or high structural integrity

- Efficient installation guided by engineering drawings

Choosing the right metal changes the way your project performs, looks and lasts. Aluminium brings lightweight strength and corrosion resistance. Mild steel brings versatility and value. Stainless steel adds durability and a clean finish. Structural steel supports the biggest builds with confidence. When you weigh these strengths against your project’s environment and goals, you set yourself up for a smoother build and a better outcome.

At the end of the day, you want materials that suit your design, your site and your long-term plans. That balance comes from understanding how each metal behaves under real conditions, not just how it looks on paper.

If you’d like guidance from a local team with years of experience across aluminium, stainless and structural builds, we’re here to help. At On The Spot Steel Fabrication, we support projects right across the Sunshine Coast and surrounding regions through high-quality work, strong communication and dependable advice. Reach out for a chat today and ask how our team can help with aluminium fabrication on the Sunshine Coast or any other fabrication work you have in mind.